Have you ever heard the expression, “My momma told me that there will be days like these”? Well, we’re having one of those days with our 1995 Jaguar XJ6. Astute readers will recall that we drove it home from the Service Department of the Jaguar Land Rover (JLR) Greenhills dealership (All British Cars, Inc. or ABC) on a Friday (January 21st) and felt that we did the right thing by having the repairs done there because our Power Wheels Magazine project car was purring and running like a proper Jaguar should.

On our drive home, our Jaguar X300 crawled smoothly through the usual Friday late afternoon Metro Manila traffic, its temperature gauge showed no signs of overheating, and it attracted a lot of attention and a couple of thumbs-up from other motorists. When we found a short stretch of “open road” or light traffic along the way, we gunned it a little to exercise the 275 horses from its fuel-injected 4.0-liter twin-cam 24-valve inline 6-cylinder AJ16 engine. It was during these exhilarating drives that we feel blessed to have rescued this abandoned British luxury vehicle and called it our own.

The letters of its license plate tells everyone how we feel about our Jag – XTC sounds like “ecstasy”.

Perceptions vs Reality

If you read our previous reports, you’ll notice that we usually ask, “How can we go wrong with a P50,000 Jaguar?” referring in jest on how low we paid for it compared to the perceived market value of 1994-1997 Jaguar X300s. We highlighted perceived market value because current market projections estimate that our project car will be worth between P1,000,000 and P1,5000,000 once we’re finished with its full restoration. After all, a pristine 1997 XJ6 with a smaller 3.2-liter engine was recently advertised for sale at P1,300,000. Please see our story “1994-1997 Jaguar XJ Sedan (X300): Has It Reached Collector Car Status?” in the Retro section of this website. (https://powerwheelsmagazine.com.ph/1994-1997-jaguar-xj-sedan-x300-has-it-reached-collector-car-status/)

We’re ecstatic that a year after we rescued it, our Jag is running and currently parked in our garage.

Of course, before our P50,000 Jaguar turns into a fully-restored XJ6 worth somewhere between P1.0M to P1.5M, we have to work on it first. And working on it also entails expenses like spare parts, fabrication, and labor costs. At JLR Greenhills/ABC for example, the service work there is charged by Man-Hours. When we restore our project car, most of these man-hours are uncharged because we do the work ourselves. Meanwhile, we farm out to specialists and experts some of the repairs that we cannot do and, as you well know, expertise and specialization costs money – lots of it.

If we will restore our Jag by the book, the repair estimate will cost more than P500,000 just for the parts alone.

Do It Yourself (DIY)

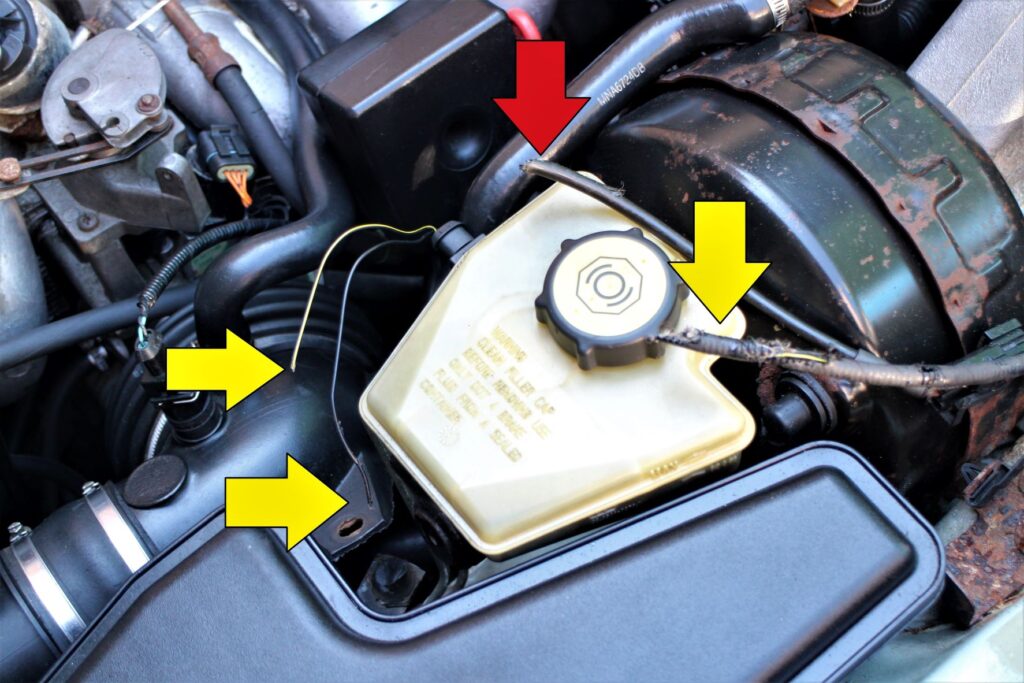

With our Jaaaaaag (wry English humor intended) in our garage, we decided to tackle some of the “easier” restoration work. One of the things that has been annoying us since we started driving it was the “FLUID” warning message on the liquid crystal digital (LCD) panel at instrument cluster. This warning is meant to call our attention to the low level of the brake fluid reservoir but a visual check showed that the reservoir was full. We checked under the master cylinder for any sign of leaks and found none. Then, we found that the wires were not connected because it was chewed by rats. We reattached it temporarily and the “FLUID” warning message ceased.

We found that the wires from the sender (yellow arrows) at the brake fluid reservoir were disconnected and chewed off along with another wire (red arrow) that we need to trace.

Because they’re a bit shorter, we spliced and connected the wires, then taped them as a temporary fix. We’ll try to get a new wiring harness or fabricate one if we can.

The “FLUID” warning message stopped. Now, we need to find out how to reset the “AIRBAG” warning message.

Curses! Stalled Again!

James Knowles, the Service Head of JLR Philippines, warned us to expect more problems with our X300, especially since it was left unattended for more than 4 years before we rescued it in January 2021. True enough, our Jag stalled again just two days after we got it home from its one-month-stay at the Jaguar Service shop. “Curses!”, we exclaimed using Dick Dastardly’s voice. The engine would start but it won’t idle and then die, just like it did in December. We remembered what ABC technician Mark Abanes said they did to get the car re-started. They blew compressed air into the fuel line to clear it of possible debris. We decide to give it a try.

Because we didn’t have an air compressor at home, we decided to use a tire pump, which came with a built-in air pressure gauge.

We disconnected the electrical connection of the fuel pump, disconnected the fuel line and used a makeshift connector to hook it to our tire pump. We pumped air at around 30 PSI several times.

After pumping air at around 30PSI into the fuel line several times, we reconnected the hose and the electrical plugs, and then started the engine, which settled into a smooth idle for about 2 minutes and then abruptly died. We tried to re-start the engine but it stalled afterwards. Thinking that we have a weak fuel pump, we stuck a thick screw driver into the fuel filler flap to relieve the built-up pressure within the fuel tank. We started the engine and it idled smoothly for about 5 minutes before conking out. On our next restart, the engine idled roughly and would stall if we didn’t modulate the gas pedal. We were beginning to run out of ideas.

We noticed that the “Check Engine” warning light remained on since our Jag’s maiden run in December.

More worrisome was this new warning light that warned us about possible problems with the 4-speed automatic transmission.

A Little Help From Our Friends

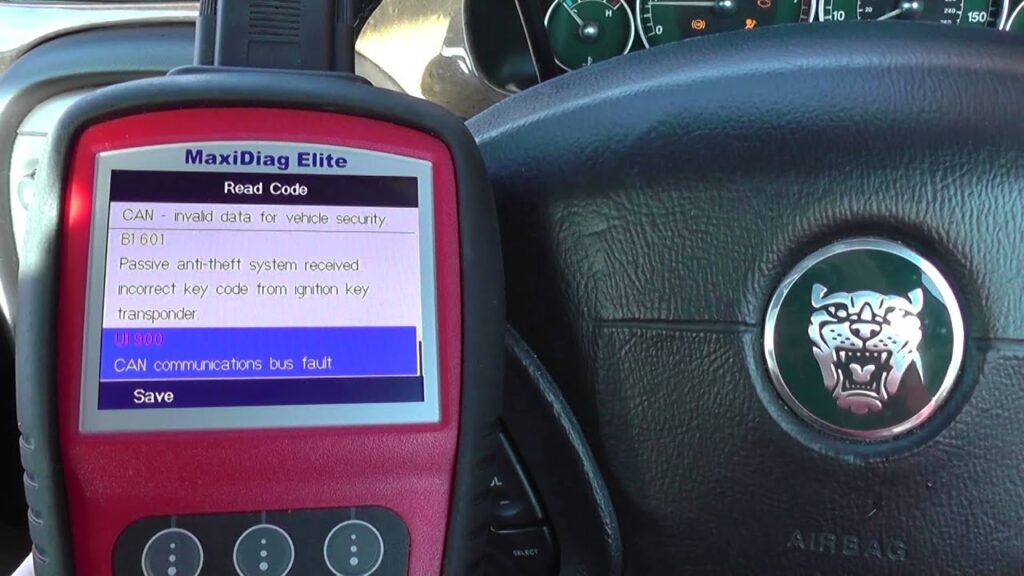

We sought help from friends who are knowledgeable about Jaguar cars and services. Paolo San Mateo, who used to work at a Jaguar dealership abroad, suggested that we should invest in a diagnostic scanning tool, which he reckons will be beneficial for our project car in the long run. He also advised us to check and clean all the sensors and senders before we focus on replacing the fuel pump because our engine problem might be caused by the ECU not getting the information it needs from the various sensors around the car.

One of our friends suggested that we should invest in an OBD scanning tool so it can guide us in repairing the faults of our Jag.

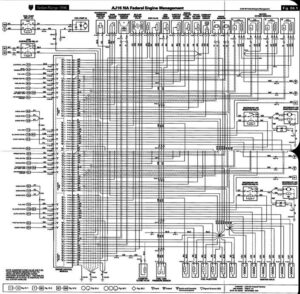

After all, our 1995 Jaguar came with sophisticated features at the time, which required complex wiring connections.

Another friend, Norbie Sison, who used to work at the service workshop of the former JLR distributor, had a more practical suggestion. He asked us to remove the six sparkplugs, mark each one with the corresponding cylinder they came from, and analyze if the air-fuel mixture is lean or rich based on the appearance of the sparkplug tips. We did so and found that the air-fuel mixture is a bit rich, which Norbie attributes to lazy, dirty or dead sensors that give the ECU false signals. He also suggested that we hook up our Jaguar to a diagnostic tool for a better understanding of its maladies.

To make a visual analysis of our AJ16’s air-fuel mixture, we had to remove each individual coil packs…

The black carbon soot from the tip of each sparkplugs meant that the air-fuel mixture was a bit rich.

After confirming our findings with Norbie, we cleaned the sparkplug tips with a soft brass brush and re-gapped them before we screwed them back into each cylinder.

One Problem After Another

After we buttoned up the sparkplugs and individual coil packs, we restarted the engine and it would idle roughly. James Knowles told us that aside from the air-flow meter at the mouth of the intake manifold, the ECU also relies on the signals from the sensors mounted on the exhaust bungs before and after the underfloor catalytic converter to provide the proper air-fuel mixture. If any of these sensors are disabled or disconnected (darn rats!) or if the mufflers are rusted, the ECU will be confused and the car will not run properly. It’s also possible that the catalytic converter can be clogged after 27 years of use.

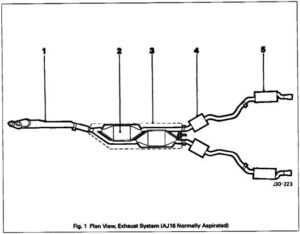

Our Jag’s exhaust includes a downpipe (1), underfloor catalytic converter assembly (2), heat shield (3), intermediate mufflers (4) and rear mufflers (5), which are rusted in our case.

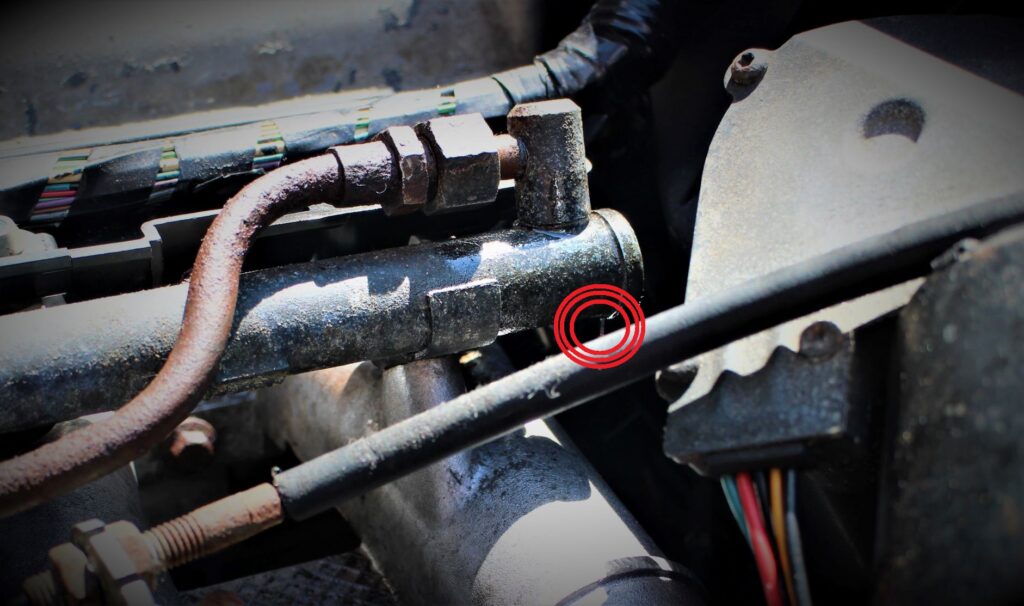

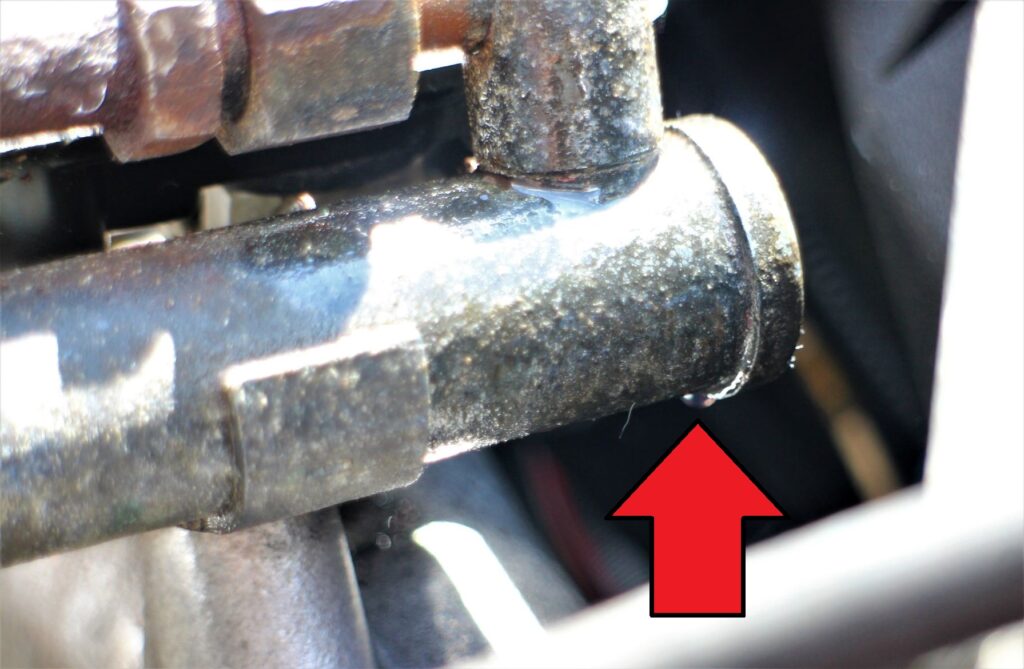

And just as we were working on a mental plan to fix the rough engine idling, we noticed that there was a leak at the fuel injection rail near the inlet. This is quite dangerous since the fuel could seep down the engine bay, get ignited, and cause a fire. We consulted our friends again and all unanimous agreed that we should prioritize the repair of the fuel rail leak before anything else. The bad news is that we have to remove each individual fuel injector to remove the fuel rail so we can have it repaired by aluminum brazing done by an expert or specialist. Uh-oh…

We noticed that the edge of the fuel rail inlet looked glisteningly wet even after the engine was warmed up.

We had to pause, take a deep breath, and gather our wits before we proceed to the next phase of our repair project. In hindsight, instead of asking “How can we go wrong with a P50,000 Jaguar?”, we should have asked, “What can go wrong with a P50,000 Jaguar?” Well, the quick, short and painful answer to that unasked question is “Plenty”. Thank God for His gifts of patience, resilience and humor. Oh boy! My Mama said that there will be days like this!

Power Wheels Magazine A Notch Above

Power Wheels Magazine A Notch Above

You learn a lot by reading plugs. A skill overlooked by a lot of so called “techies”. But one glance can tell you immediately what to focus on.

With regards to the fuel rail, one quick way to establish what it’s made of is with a magnet. If it sticks, definitely steel. Brazing techniques for steel will use a different “filler metal”.

Wow, thanks again, Norbie, for lending your expertise and helping us with our Jaguar X300 project car

One thing, if you pumped air into the fuel supply line to the rail, I do hope you disconnected its end from the rail. If you didn’t do that, if there was debris in the line, you would have succeeded in pumping said debris to the injectors clogging them further!?

You might want to try a fresh set of plugs. But in the event the engine still runs roughly on idle or stalls, put back the old set first. No sense screwing up a new set while you’re still in the midst of trouble shooting.

Another potential source of a bad idling situation is a malfunctioning idle air control valve. But, before doing anything drastic, the car should really be scanned for faults so as to zoom in on what the computer sees. A check engine light remains on if there’s a permanent fault in the system.

The IACV is a metering device that allows air to flow through a closed throttle valve to allow the engine to idle. Typical issues would be a dead motor or clogging of the air passages.